Multi double layers plastic pe body lotion products extrusion blow molding machine making canister hdpe 200ml bottle jar

Product Description

Product Description

It is 5L 1 gallon single station/double station BSM70D-6L machine for producing HDPE, PP, PVC max.

6L plastic products, like 500ml bottle, 1000ml jerrycan, small container, motor oil drum or engine oil drum, and plastic jar.

Besides, it could choose different continuous heads based on actual plastic products. Usually single head is for 3-5L, double head(160mm central distance) is for about 2L, 1L bottle, triple head is for 500ml bottles, four head is for small bottle. Quick extrusion, stable running, easy operation and mature technology.

6L plastic products, like 500ml bottle, 1000ml jerrycan, small container, motor oil drum or engine oil drum, and plastic jar.

Besides, it could choose different continuous heads based on actual plastic products. Usually single head is for 3-5L, double head(160mm central distance) is for about 2L, 1L bottle, triple head is for 500ml bottles, four head is for small bottle. Quick extrusion, stable running, easy operation and mature technology.

Max. Product Volume | (L) | 6 |

Theoretical Output | (PC/h) | 700x2 |

Screw Diameter | (mm) | 70 |

Screw L/D ratio | (L/D) | 24-30 |

Screw drive power | (KW) | 18.5-30 |

Screw heating capacity | (KW) | 12-14.5 |

Output of HDPE | (kg/h) | 70-95 |

Oil pump drive power | (KW) | 5.5-7.5 |

Clamping force | (KN) | 70 |

Platen size | (WxH) mm | 368x430 |

Platen Opening Stroke | (mm) | 178-538 |

Max. Die diameter | (mm) | 150 |

Central distance of bi-die | (mm) | 150-200 |

Max. Die Diameter (Bi-die) | (mm) | 100 |

Central distance of three-die | (mm) | 110-140 |

Max. Die Diameter (three-die) | (mm) | 70 |

Central distance of four-die | (mm) | 70-100 |

Max. Die Diameter (four-die) | (mm) | 45 |

Average Energy Consumption | (kw/h) | 18.5 |

Blowing pressure | (Mpa) | 0.6 |

Air Consumption | (M3/MIN) | 0.4 |

Cooling water pressure | (Mpa) | 0.3 |

Water consumption | (L/MIN) | 70 |

Size of machine | (LxWxH) /m | 3.5x2.1x2.6 |

Weight of machine | (TON) | 8.0 |

Product Details

Extrusion system: Extrusion motor and gear box offer the power for screw. Meanwhile screw and barrel with strong material make sure plasticizing plastic material well, ceramic material heater with evenly and quickly heating function!

Head system:

Adopt continuous type, material central coming in, eject material quickly and easy change the head!

Clamping system: It has clamping plate and cylinder, linear guide, slider, transducer... Mold is fixed on the plate. All components make sure mechanical movement precision, stable and quick!

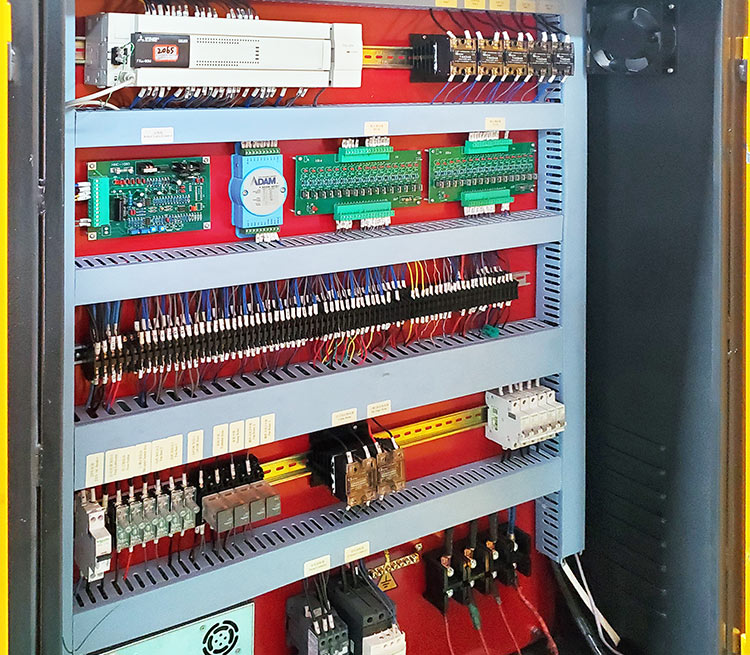

Electrical control: It has operation touch screen, PLC, contact switch, air switch, delay, voltage stabilized power, inverter ...We could input, modify and monitor the parameter of heating, pressure, time, alarm... to control whole machine’s action parameter by touch screen. It has two operation languages, Chinese and English!

Hydraulic system: It has hydraulic motor, valve, pump, oil tank, oil cooler, tube... Offer power for mechanical action, meanwhile proportional valve is controlled by oil flow pressure for transfer digital signal into mechanical action, to control the action of blow pin, clamping structure, head and extrusion.

Die head can be choosed

Continuse type Extrusion blow molding machine can be choosed.

Related products

Customer Photos

Our service

Choosing the suitable machine: We have a professional team, electrical engineers, mechanical engineers, commissioning engineers...Our engineers have been in this field over 18 years, have rich experiences. According to the customer’s plastic products and requirements , we could offer good solution based on experiences. And we also could recommend the related auxiliary machines to get a whole production line.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Customer’s visit: Before playing the order, warmly welcome to visit our workshop if customer interests. We will introduce our machines on site.

Delivery time: we will finish manufacturing and testing within delivery time, make sure customer’s production schedule. During the production process, we also will share the production progress photos and testing video with customer.

Warranty time: our warranty time is 12months after the delivery. During this period, any quality problem of the machine, we will send the replacement parts by express freely. If the buyer meet any technical problems, we will provide the support through remote control.

Training, installation: when the machine reaches the buyer’s factory, the buyer could tell us, we will dispatch an engineer to the buyer’s factory to help install and test the machine until it runs normally. Meanwhile, we also could help train the customer’s employee.

Packing & Shipping

1) The machine body is covered by waterproof film firstly, and then fixed on exported wooden pallets with bolts and wires. 2) The electric controlling parts and spare parts are loaded separately in wooden box. 3) The auxiliary equipments are packaged in wooden box as well. 4) All wooden material is fumigation certificated and safe for exporting to all over the world.

Recommend Products

Product Categories : Extrusion blow molding machine > 0-20L

Premium Related Products

Other Products

Hot Products

PET Bottles and Preform Plastic Injection Molding Machine(KS PET270)Precision Plastic Products Injection Molding MachinePP PVC Preform Injection Molding Machine(KS PET130)Injection Molding Machine(KM(L) L Type)Mobile Phone Shell Case Plastic Machine(KS 360H)Injection Molding Machine(KS 270H)Plastic Auto Parts Servo Injection Molding Machine(KS140)Cosmetic Box Servo Injection Molding Machine(KS530)Servo System Plastic Injection Molding Machine(KS460)Pumps Injection Molding MachinesHydraulic System Injection Molding MachinesPlastic Products Servo machines(70t-1100t)Automatic Injection Molding Machines(70t-1100t)Plastic Making Injection Molding MachineServo Motor Pipe Plastic Injection Molding MachineTooth Brush Making Injection Molding Machine(70ton-780ton)