vision inspection solution for quality control

Product Description

Vision Inspection Solution for Quality Control

Product Description

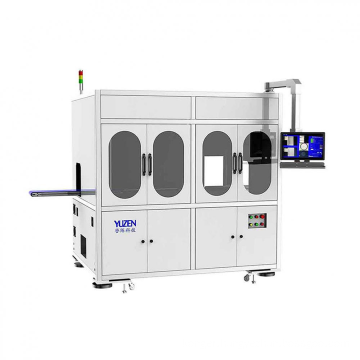

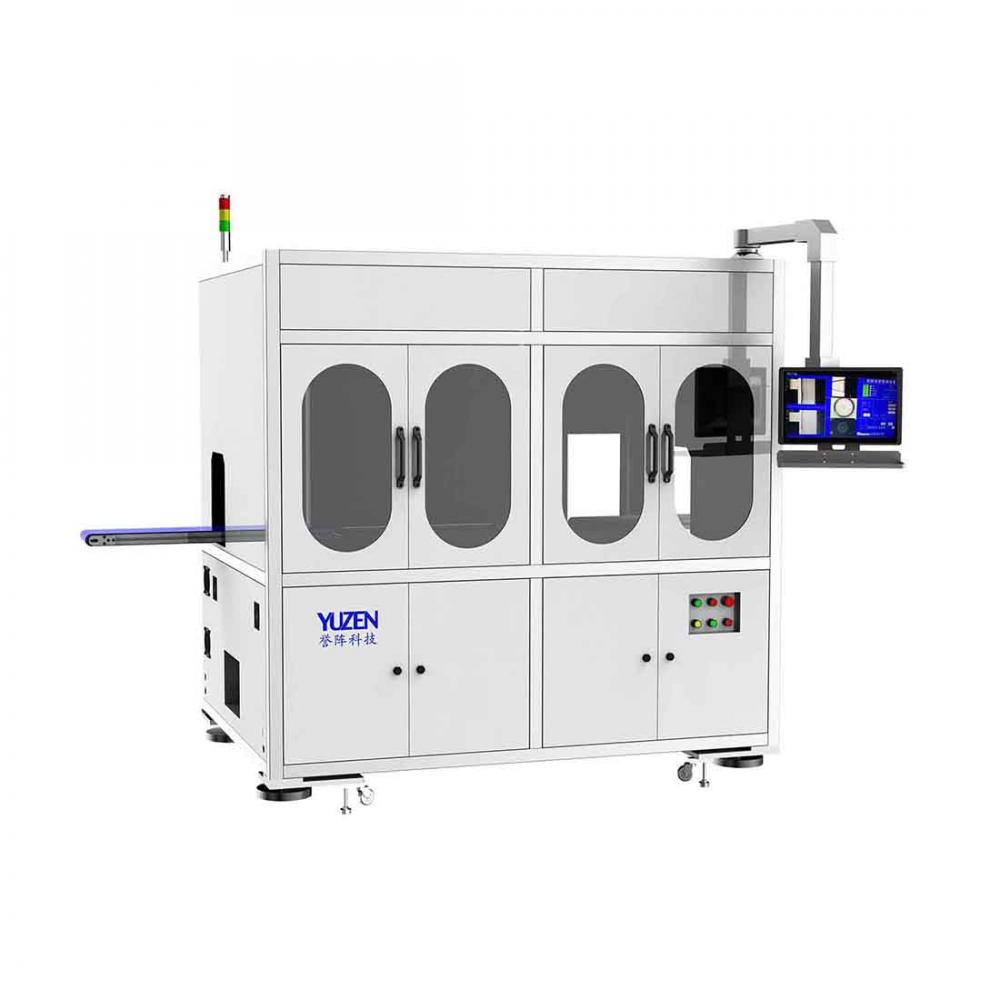

Industrial Vision System is a camera-based system that uses statistical learning to sort and inspect cap and bottle . The parts traverse the Inspection Vision System by being rolled along an angled rail so that the camera can get 360 degrees of images to inspect plastic bottle and cap. If you like our Visual Inspection Machine, feel free to contact with us.

The visual inspection machine and bottle vision system for cosmetic bottles can not only detect the appearance defects of cosmetic bottles, but also can be widely used in the inspection of transparent or non-transparent bottles such as dairy bottles, daily chemical bottles, and beverage bottles. Main inspection contents: Detecting appearance defects such as lack of material in flash, black spots, uneven thickness, deformation, etc. It can be connected with back-end auxiliary machines such as leak detectors, balers, and case packers, and is equipped with high-speed bottle inspection machines. It can meet the simultaneous connection requirements of multiple devices, and the maximum detection speed can reach 36,000 bottles/hour. It is equipped with special light source design and secondary photography products, which can realize comprehensive inspection of the inside and outside.

Our product list

Plastic bottle vision system

Medicine bottle vision system

One machine detects multiple varieties.

Proven packet inspection software;

Compact design saves space for occupying space.

Multifunctional bottle vision system

High precision and more comprehensive defect detection system;

One machine corresponds to multiple varieties.

Intelligent production management;

Multiple optional configurations

Milk bottle vision system

Comprehensive detection of containers;

There is no blind area for multi cameras.

Production statistics management

Multifunctional milk bottle vision system

Connect multiple blowing machines.

High speed and high precision;

Optimize production technology.

Daily chemical bottle vision system

Various bottle type solutions;

Customized according to product characteristics.

Solve complex bottle type’s blind area problem

Wild mouth vision system

Multiple defects in PET bottles were detected simultaneously.

One machine corresponds to hundreds of products.

Connect automatic packing machine to realize unmanned production of blowing bottle

Cap vision system

Medical cap vision system

One machine detects multiple varieties.

Proven packet inspection software;

High speed detection meets production needs.

High speed cap vision system

One machine is compatible with multiple varieties.

The maximum speed can reach 2500 / min.

Various specifications can be selected.

Water beverage bottle cap vision system

Preform vision system

Standard bottle detection machine

All kinds of defects were detected.

There is no blind area for multi cameras.

In moud labeling vision system

The labeling effect is simultaneously detected with the appearance of the container.

Automatic stacking cache;

High efficiency and labor saving

Pharmaceutical spray pump vision system

The content of the test is comprehensive.

High standard design in pharmaceutical industry;

Multiple optional configurations

Cap seal vision system

Liquid level vision system

High speed on-line detectionCompact design saves space.

Intelligent production management

Contact us if you need more details on Vision Inspection Solution. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Vision Solution Sale、Inspection Solution Hot Selling. If these products fail to match your need, please contact us and we would like to provide relevant information.Product Categories : Visual inspection system > Industrial Vision System